Essential Tools and Techniques

Diy woodworking christmas gifts – Creating beautiful and functional woodworking Christmas gifts requires the right tools and techniques. This section Artikels the essential tools you’ll need, categorized for clarity, along with safe usage practices and common woodworking joints perfect for gift-making. Proper technique and safety are paramount to ensure a positive and injury-free experience.

Essential Woodworking Tools, Diy woodworking christmas gifts

Choosing the right tools is crucial for success. The tools listed below are categorized by their primary function, providing a comprehensive starting point for your woodworking projects. Remember to always prioritize safety when using any power tool.

| Category | Tool | Description |

|---|---|---|

| Measuring | Measuring Tape | Essential for accurate measurements of materials. |

| Measuring | Combination Square | Used for marking precise angles and checking squareness. |

| Measuring | Marking Gauge | Creates parallel lines at a consistent distance from an edge. |

| Cutting | Hand Saw | For cutting wood by hand, offering precise control in smaller projects. |

| Cutting | Circular Saw | A power saw for quick and efficient straight cuts in larger pieces of wood. |

| Cutting | Jigsaw | Used for curved and intricate cuts. |

| Shaping | Chisels | For shaping wood, removing material, and creating joints. |

| Shaping | Sandpaper (various grits) | Used for smoothing surfaces and removing imperfections. |

| Shaping | Random Orbital Sander | A power tool for efficient sanding, creating a smooth finish. |

| Finishing | Wood Glue | Used to bond pieces of wood together. |

| Finishing | Clamps | Hold pieces of wood securely during gluing and other processes. |

| Finishing | Wood Stain/Finish | Provides protection and enhances the appearance of the wood. |

| Finishing | Brushes/Rags | For applying stain and finish evenly. |

Safe Tool Usage Techniques

Safe and proper tool usage is vital to prevent injury and ensure quality work. Always follow the manufacturer’s instructions for each tool.

- Measuring Tape: Always ensure the tape measure is properly extended and retracted to avoid snapping.

- Hand Saw: Use a push/pull motion, keeping your fingers clear of the blade.

- Circular Saw: Always use a blade guard and wear safety glasses. Secure the wood firmly before cutting.

- Jigsaw: Use a clamping system to secure the workpiece, and always wear a dust mask.

- Chisels: Use a mallet to strike the chisel, keeping your fingers out of the way. Use a push cut rather than a pull cut.

- Sandpaper/Sander: Always sand in the direction of the wood grain to avoid scratches. Use appropriate dust collection methods for power sanders.

- Wood Glue: Apply glue evenly to both surfaces, clamp firmly, and allow sufficient drying time.

- Clamps: Ensure proper clamping pressure to prevent movement during glue drying. Never put your fingers between the clamp jaws.

- Wood Finish: Work in a well-ventilated area and wear appropriate personal protective equipment (PPE) such as gloves and a respirator.

Common Woodworking Joints

Understanding different woodworking joints is crucial for constructing strong and aesthetically pleasing Christmas gifts. The choice of joint depends on the project’s requirements and the desired look.

- Miter Joint: This joint uses angled cuts to join two pieces of wood at a corner, typically at 45 degrees. Imagine two pieces of wood forming a perfect 90-degree corner, with each piece cut at a 45-degree angle to meet. It’s commonly used in picture frames and boxes.

- Dovetail Joint: A strong joint created by interlocking “tails” and “pins” cut into the ends of two pieces of wood. Think of interlocking fingers, but made of wood. This joint is incredibly strong and is often seen in high-quality drawers and furniture.

Finishing Techniques for a Professional Look

Achieving a professional finish on your woodworking Christmas gifts elevates them from simple crafts to cherished keepsakes. Proper sanding and the application of a suitable finish are crucial steps in this process, significantly impacting the final appearance, durability, and longevity of your creations. This section details the necessary techniques to ensure your gifts look their best.

Sanding Techniques

Thorough sanding is the foundation of any successful finish. It creates a smooth surface, allowing the finish to adhere properly and preventing imperfections from showing through. The process involves using progressively finer grits of sandpaper to remove scratches and achieve a polished look.

- Start with a coarser grit sandpaper (e.g., 80-100 grit) to remove any major imperfections or saw marks. Sand with the grain of the wood, applying even pressure and avoiding excessive force.

- Gradually move to finer grits (e.g., 120, 180, 220 grit), sanding each time with the grain. This removes scratches left by the previous grit and creates a progressively smoother surface. The goal is to remove all previous sanding marks before moving to the next finer grit.

- For the final sanding, consider using a very fine grit (e.g., 320 or higher) to achieve an ultra-smooth surface. This is particularly important for projects that will be handled frequently or that will receive a clear finish, such as varnish or oil.

- After each sanding stage, wipe the surface clean with a tack cloth to remove any dust particles. Dust can clog sandpaper and create imperfections in the finish.

Finishing Options and Their Effects

Several finishing options exist, each offering unique characteristics and impacting the final appearance and durability of your project.

- Paint: Provides excellent protection and allows for a wide range of colors and finishes. It hides wood grain but can chip or peel over time if not properly applied.

- Stain: Penetrates the wood, enhancing its natural color and grain. Stains offer less protection than paint but allow the wood’s beauty to shine through. Different types of stains (water-based, oil-based) exist with varying penetration and drying times.

- Varnish: Creates a hard, protective layer that resists scratches and moisture. It enhances the wood’s natural beauty while providing durability. Different types of varnish (e.g., polyurethane, spar varnish) offer different levels of gloss and durability.

- Oil: Penetrates the wood, nourishing it and enhancing its natural beauty. Oil finishes offer less protection than varnish but provide a more natural feel and look. Linseed oil and tung oil are common choices, each with its own drying time and level of protection.

Finishing Process Flowchart

The following flowchart visually represents the step-by-step process of finishing a wooden Christmas gift. It illustrates the sequence of sanding and finishing stages, emphasizing the importance of each step for a professional-looking result.Imagine a flowchart with the following steps:

1. Start

Raw wooden project.

2. Sanding

80-grit, 120-grit, 180-grit, 220-grit, 320-grit (each step includes cleaning with tack cloth).

3. Choice of Finish

(Diamond with branches leading to Paint, Stain, Varnish, Oil).

4. Application

(Different application techniques for each finish type – brushing, spraying, wiping).

5. Drying

(Time varies depending on finish and environmental conditions).

6. Inspection

Check for imperfections, re-sand if necessary.

7. Final Coat (if needed)

Apply additional coats for deeper color or enhanced protection.

8. Drying

Final drying time.

9. End

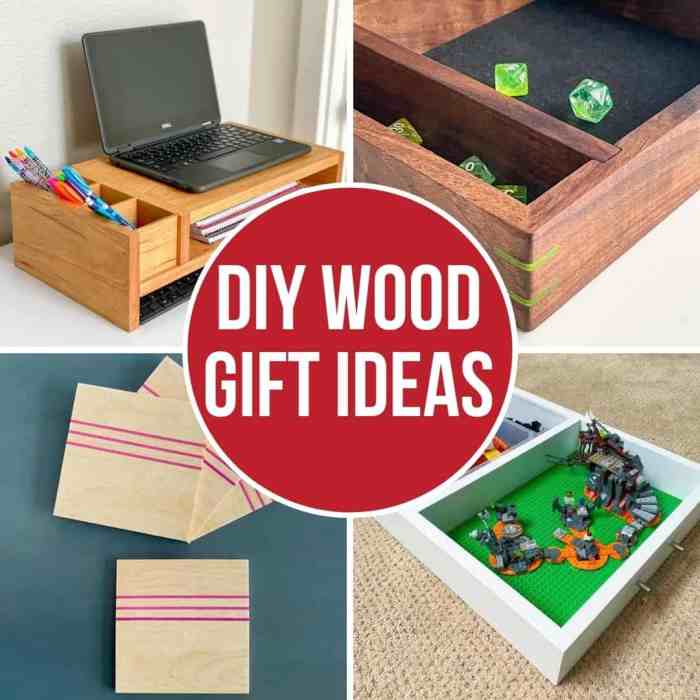

DIY woodworking offers a fantastic avenue for crafting unique Christmas gifts, showcasing personal skill and heartfelt sentiment. If you’re seeking inspiration for a truly special present, consider checking out resources dedicated to christmas present boyfriend diy ideas; they often feature projects adaptable to woodworking. From charming coasters to intricate shelves, the possibilities for personalized, handcrafted wooden gifts are endless.

Finished wooden Christmas gift.

Adding Personal Touches and Decorations

Transforming a simple woodworking project into a cherished Christmas gift involves adding personalized elements that reflect the recipient’s tastes and your unique artistic flair. This goes beyond mere functionality; it’s about imbuing the gift with a sense of warmth and connection. The following techniques allow you to elevate your woodworking gifts from functional to truly special.Adding personalized elements and festive decorations enhances the overall appeal and sentimentality of your DIY woodworking Christmas gifts.

Careful consideration should be given to both the aesthetic and structural aspects to ensure the decorations complement, rather than detract from, the piece. Overly elaborate decorations might compromise the structural integrity, while understated elements can add a touch of elegance.

Personalized Engraving and Burning

Engraving and wood burning offer excellent methods for adding personalized messages, names, dates, or even simple designs. Engraving, typically done with a rotary tool or specialized engraving machine, creates crisp, clean lines ideal for lettering. Wood burning, using a wood burning tool with various tips, allows for more artistic freedom, creating shading and texture within the design. For example, you could engrave a recipient’s initials onto a wooden cutting board or burn a festive snowflake pattern onto a small wooden ornament.

The contrast between the burned/engraved area and the natural wood creates a visually appealing effect.

Incorporating Festive Decorations Without Compromising Structural Integrity

Festive decorations can significantly enhance the aesthetic appeal of your gifts. However, it’s crucial to ensure these additions do not compromise the structural integrity of the piece. For instance, attaching heavy embellishments to delicate items could lead to damage or breakage. Consider using strong adhesives appropriate for wood and the chosen embellishment material. Lightweight decorations, such as small ribbons, painted details, or carefully applied stencils, are less likely to cause structural issues.

When attaching ribbons, ensure they are securely fastened and do not create stress points on the wood.

Creating a Custom Wood Burning Pattern: The “Winter Forest” Design

This example details creating a custom wood burning pattern, the “Winter Forest” design. The design features a stylized silhouette of three pine trees against a backdrop of a crescent moon and a few scattered stars. The trees are rendered with varying heights and slightly different shapes to add visual interest. The moon is a simple, slightly imperfect crescent, implying a natural, hand-drawn feel.

The stars are small, evenly spaced dots, creating a sense of depth and a starry night sky. To create this design, first sketch it lightly onto the wood with a pencil. Then, using a wood burning tool with a fine tip, carefully trace the Artikel of each element. Gradually add shading and detail by varying the pressure and speed of the tool.

Finally, you can use a slightly broader tip to add subtle shading around the trees and moon to enhance the three-dimensional effect. The result is a charming, rustic scene that perfectly complements the Christmas theme. The contrast between the burnt areas and the lighter wood creates a beautiful visual effect.

Questions Often Asked: Diy Woodworking Christmas Gifts

What safety precautions should I take when using woodworking tools?

Always wear safety glasses, use appropriate hearing protection for noisy tools, and ensure your work area is well-lit and free of clutter. Follow the manufacturer’s instructions for each tool and never rush the process.

How can I prevent wood from warping or cracking?

Properly acclimate your wood to your workshop environment before starting a project. Use appropriate joinery techniques and finish your pieces with a sealant to protect them from moisture.

Where can I find affordable wood for my projects?

Local lumber yards, online retailers, and even reclaimed wood sources can offer cost-effective options. Consider using smaller pieces of wood or repurposing scrap wood to minimize expenses.

What’s the best way to clean up after a woodworking project?

Sweep or vacuum up sawdust and wood shavings. Clean your tools thoroughly and store them properly. Dispose of wood scraps and finishing materials responsibly.